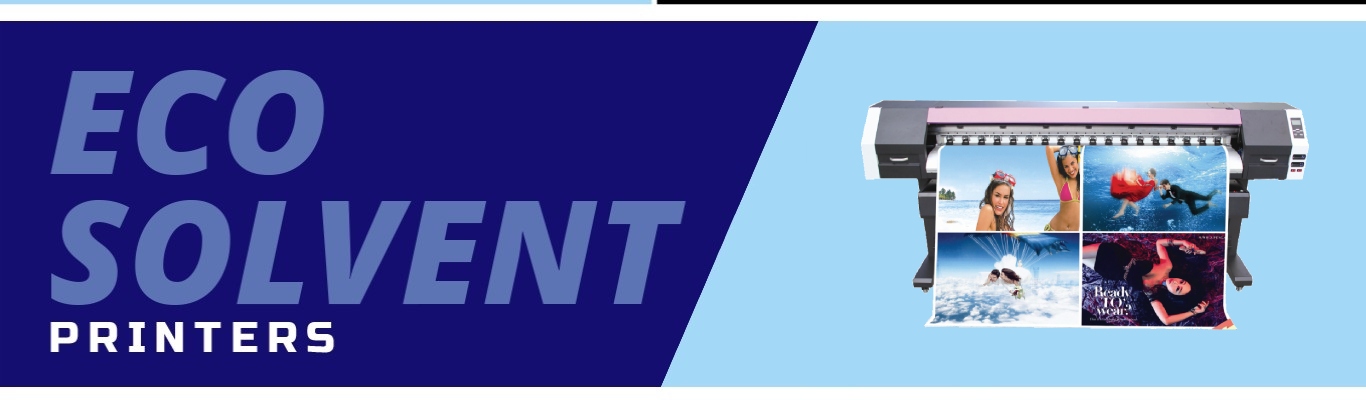

Eco Solvent Printer XEDA XP 6

Siare has always worked towards making the products more efficient and technology-friendly. Our Xeda DX6 eco-solvent roll-to-roll printer is made with high precision for flawless industrial printing. The printers have unique ink-dot printing technology which helps to print with gradual change and the feathering technology removes all the printing lines.

The machines are smart to meet the latest industrial needs; they have automated paper feeding, ink pumping, print head wiping and cleaning. It also consists of auto bulk ink feeding system with four exterior ink tanks and also with automatic paper feeding ink, pumping, print head wiping and cleaning.

For faster drying, the printers consist of front and back heating system with heat controller. Our printers accommodate optical fibre instead of flat cable for inner communication and better printing.

You can use our solvent printers in various industries like:

All our products undergo a rigorous testing procedure to ensure the best quality is being delivered to you. In addition, our products adhere to all the international standards to match the dynamic industrial requirements.

We aim to provide futuristic solutions to our consumers and meet the needs of the ever-evolving industry with our intelligent solutions.

All our products undergo a rigorous testing procedure to ensure the best quality is being delivered to you. In addition, our products adhere to all the international standards to match the dynamic industrial requirements.

The machines are smart to meet the latest industrial needs; they have automated paper feeding, ink pumping, print head wiping and cleaning. It also consists of auto bulk ink feeding system with four exterior ink tanks and also with automatic paper feeding ink, pumping, print head wiping and cleaning.

For faster drying, the printers consist of front and back heating system with heat controller. Our printers accommodate optical fibre instead of flat cable for inner communication and better printing.

You can use our solvent printers in various industries like:

- Outdoor car sticker applications: We can see many ads often stuck to the buses; they are done with the outdoor photo machine, the pictures and bright and weather-proof for a stunning view.

- Corridor lightbox, Advertising, store advertising, subway station and bus station advertising Every day we see hundreds of advertisements with lightboxes in other allies or highways, which look attractive at night.

- Outdoor advertisement canvas cloth, flag etc. These are popular among various industries, often printed with water-based ink; these advertisements are resistant to all weather conditions and do not fade for much longer.

- Roll up banner: Roll-up banners are also one type of advertisement we can see daily; they are popular among medium-sized retailers.

- Wallpapers and photo papers

All our products undergo a rigorous testing procedure to ensure the best quality is being delivered to you. In addition, our products adhere to all the international standards to match the dynamic industrial requirements.

We aim to provide futuristic solutions to our consumers and meet the needs of the ever-evolving industry with our intelligent solutions.

All our products undergo a rigorous testing procedure to ensure the best quality is being delivered to you. In addition, our products adhere to all the international standards to match the dynamic industrial requirements.

Technical Specification

| Model | F10 – ST1802 | ST – S1800 | ST – S1600 |

|---|---|---|---|

| Printhead | drop-on-Demand Piezo Inkjet Tech. | drop-on-Demand Piezo Inkjet Tech. | drop-on-Demand Piezo Inkjet Tech. |

| Ink Color Type Ink Supply | 2×4 C.M.Y.K Dye Sub Ink Bulk Ink With German Filter | 2×4 C.M.Y.K Water / Solvent based Ink for Dx5 Bulk Ink With German Filter | |

| Print speed Production Mode Resolution Mode Hi-Res Mode | 30m2 /h 30m2 /h 20m2 /h | 20m2 /h 15m2 /h 10m2 /h | 18m2 /h 13m2 /h 09m2 /h |

| Drying Heating Temp | Pre Heater / Post Heater Ambient Temp : 80OC, Serving Temp : 40OC – 60OC | ||

| Media Size Type Transportation | 1800mm Hi Glossy Photo Paper, Canvas, PP, Film Backlite / Front-lite etc Constant Tension Feeding System | ||

| Cleaning | Auto – Cleaning / Auto – Wiping | ||

| Interface | Network / USB Interface | ||

| Environment | Temp : 18OC – 29OC Humidity: 50OC – 80OC | ||

| Power | Frequency : 50Hz. Voltage : AC 220V (+/- 10%) | ||

| Dimension | LxWxH (mm) : 3150 x 800 x 1200 / L3730 x w1010 x H1210 | ||

| N.W | 220KG / 350KG |

KEY FEATURES

Specially enforced stainless steel for long-life strong and stable frame structure.

Waste ink collection system.

Double differential speed control design,auto smart tention bar,to ensure unattended printing to the very end of each media roll.

Specially enforced stainless steel for long-life strong and stable frame structure.

Double differential speed control design,auto smart tention bar,to ensure unattended printing to the very end of each media roll.

Previous

Next